Predictive analytics in manufacturing enables businesses to anticipate trends, optimize operations, and improve decision-making. By analyzing historical data and using machine learning algorithms, manufacturers can predict demand fluctuations, equipment failures, and probable supply chain disruptions. This proactive approach reduces costs, minimizes downtime, and enhances overall efficiency.

Salesforce Data Cloud helps manufacturing companies with seamless predictive analysis. Its unified platform allows manufacturers to seamlessly integrate data from various sources, facilitating them to get a comprehensive view of operations. The platform’s AI-powered tools help organizations gain real-time insights, predict future trends, and take actionable steps to optimize performance.

How Predictive Analytics in Manufacturing Helps to Automate Prospecting and Enhance Productivity?

Predictive analytics in manufacturing plays a crucial role in automating prospecting and boosting productivity. It provides manufacturers with actionable insights that helps them make decisions solely based on data, optimizing efficiency. By leveraging historical data and machine learning prediction models, manufacturers can predict customer behavior, market trends, and operational challenges.

Predictive analytics enables manufacturers to analyze past customer behavior, product usage, and spending patterns. This allows them to identify potential leads and tailor marketing strategies for cross-selling or up-selling opportunities. It also enhances productivity by forecasting equipment performance and showing when maintenance is required.

With predictive analytics, manufacturers can reduce unplanned downtime and improve operational efficiency. This helps them proactively schedule maintenance, minimizing disruptions and keeping production lines running smoothly. Additionally, machine learning predictive models can optimize supply chain processes, improving inventory management and reducing waste.

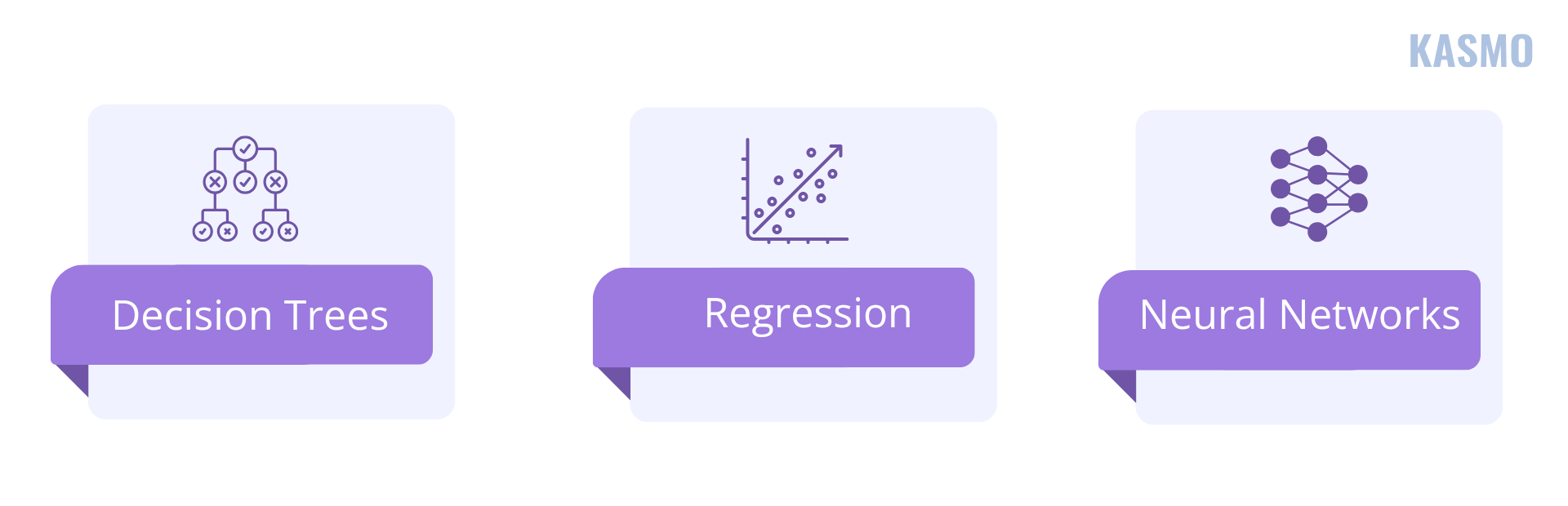

Types of Predictive Models Manufacturers Can Use to Understand Customer Behavior and Predict Market Demands

There are three primary type of predictive models that manufacturers can use:

- Decision Trees: This type of predictive analytics model helps manufacturers visualize different decision paths and outcomes. This model also helps them understand how factors like customer preferences influence buying decisions.

- Regression Analysis: This predictive analytics model uses statistical methods to identify relationships between variables (e.g., customer demographics and market trends), forecasting demand and predicting price fluctuations.

- Neural Networks: This model consists of advanced algorithms that can identify complex, nonlinear relationships in data, enabling manufacturers to predict shifts in demand and optimize inventory based on customer behavior patterns.

What Benefits Will Manufacturers Get from Investing in Predictive Analytics?

As both customers and the market continue to shift towards a more digital-first approach, it is crucial for manufacturers to invest in predictive analytics services that can help in reducing overhead costs and optimizing efficiency. Here are some benefits manufacturers can get by investing in predictive analytics:

- Boost Efficiency: Predictive analytics shows the probable areas where manufacturers can take action to eliminate the weak spots in their operations. It also helps you to streamline manufacturing processes, reduce downtime and enhance overall productivity.

- Improve Quality Assurance: With real-time monitoring, predictive analytics in manufacturing ensure consistent product quality by detecting defects or variations early in the production process.

- Optimize Inventory Management: Accurate demand forecasting helps maintain optimal inventory levels, and manufacturers can avoid excess stock or shortages.

- Increase Revenue: Predictive analytics in manufacturing enhance efficiency, reduce costs, and help manufacturers maintain a consistent quality, increasing both revenue and profit margins.

- Facilitate Data-Driven Decisions: Manufacturers need to rely on accurate data to make more informed decision-making. With predictive analytics this becomes easy for manufacturers, as they provide insights solely on the data collected by the system. This prevents in making intuition-based choices and increasing errors.

- Enhance Workplace Safety: Predictive analytics help manufacturers identify potential safety hazards and implement preventive measures that employees are provided with a safe working environment.

Steps Manufacturers Can Follow to Get Started with Predictive Analytics

By understanding how you can get started with predictive analytics, here are four simple steps you can follow:

Centralize Data

Collect data from various sources, including production lines, customer feedback, and supply chains, and centralize it into one unified system. To avoid data silos, consolidating all the different types of data from multiple sources is the first step in making your data accessible for drawing insights.

Clean and Prepare the Data

After gathering data, you need to clean and pre-process data to ensure accuracy and consistency. In this step you can ensure the integrity of the collected data by removing duplicates, filling gaps, and standardizing formats. This ensures the machine learning predictive model can work with reliable data.

Develop Predictive Model

Leverage analytics platforms and machine learning prediction tools to create predictive models tailored to your business needs. These models can forecast demand, predict equipment failures and production schedules.

Implement and Act on Data-Driven Insights

Once you have decided on the type of predictive model, use its insights to take data-driven decisions. This could involve adjusting inventory levels, scheduling preventive maintenance, or making real-time production adjustments. Manufacturers can embed these insights into daily workflows, equipping teams to act on them swiftly.

How Salesforce Data Cloud Optimizes Predictive Analytics in Manufacturing?

Salesforce Data Cloud is transforming predictive analytics in manufacturing by offering a unified, real-time data platform. This unified platform empowers manufacturers to leverage vast amounts of data for smarter decision-making and improved operational efficiency. With Data Cloud’s robust capabilities, manufacturing companies can optimize their entire supply chain management and customer service— by providing actionable insights powered by AI agents and advanced analytics.

Manufacturing companies often struggle with data silos across multiple systems, which hinders their ability to gain a comprehensive view of their operations, customer data and supply chain. Salesforce Data Cloud breaks down these data silos by unifying structured and unstructured data from diverse sources such as production machines, ERP systems, supply chain logs, and customer interactions.

By consolidating this data, manufacturers can gain a 360-degree view of their operations and leverage predictive models that help forecast demand, optimize production schedules, and manage supply chain risks.

By integrating external data sources, including market trends and customer behavior patterns, manufacturers can better anticipate any changes in demand spikes or dips. With this knowledge they can proactively adjust production volumes, inventory levels, and workforce schedules to meet future demands. This improves operational efficiency and reduces waste and minimizes the costs of overproduction.

Salesforce Data Cloud can also analyze historical data, supplier performance, and external factors such as geopolitical events, weather patterns, and raw material availability, to help manufacturers take data-driven decisions that reduce errors.

Identifying potential disruptions or opportunities with Data Cloud, manufacturers can predict and mitigate supply chain risks, ensuring smoother operations. Whether it’s predicting delays in shipments or determining the most cost-effective suppliers, Data Cloud allows manufacturers to make data-driven decisions that enhance supply chain resilience.