IoT in Manufacturing: Driving Efficiency and Maximizing Profits

IoT in manufacturing industry, or sometimes referred to as Industrial Internet of Things (IIoT) provides manufacturers an opportunity to transform their manufacturing operations and enhance their entire business operations. According to marketsandmarkets the revenue of global IoT for manufacturing market is projected to increase to $87.9 billion by 2026. This growth is possible because there has been an increasing need for monitoring and increasing the shelf life of assets. Manufacturers have started moving towards cloud migration and adoption of cloud services for seamless supply chain management.

The several benefits of IoT in manufacturing are encouraging companies to invest more in IoT. In this blog we will talk about the difference between IIoT and IoT, the advantages of implementing IoT in manufacturing, how Snowflake helps in creating IoT solutions and why you should choose Kasmo for creating innovative business solutions. Let’s dive in!

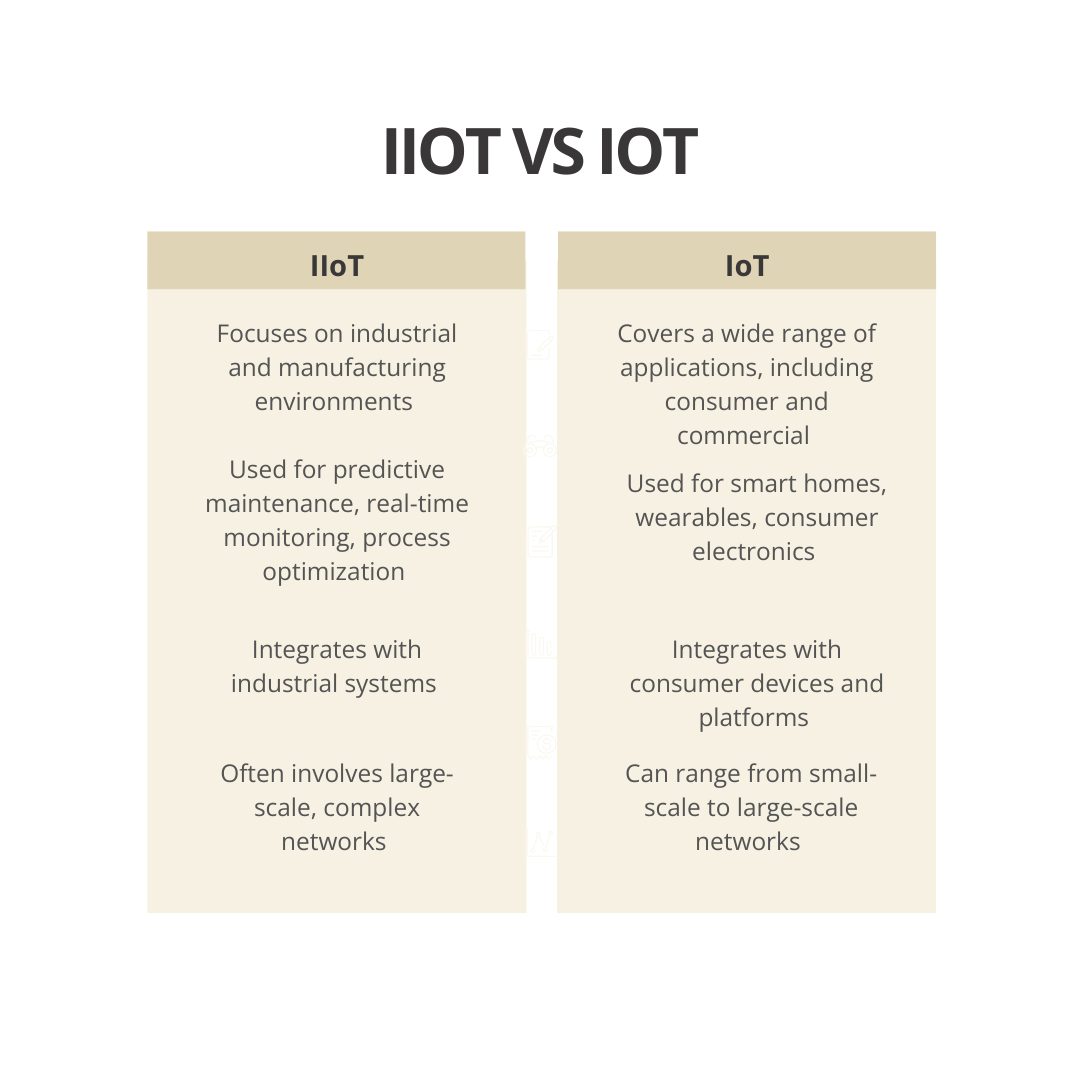

What is the Difference Between IIoT and IoT in Manufacturing?

Before we discuss the components and advantages of IoT in manufacturing, it is important that companies understand the differences between IIoT and IoT. Let’s have a look at this table:

Components of IoT

IIoT is a sub-category of IoT. IIoT is crucial technology in Industry 4.0. Let’s have a look at its components:

- Devices: Physical items equipped with smart sensors to collect and transmit data. Common sensors include temperature, pressure, humidity, light, proximity detection, and Radio-Frequency Identification (RFID) tags.

- User Interface (UI): It is an interactive program that allows manufacturers to monitor and manipulate data from IoT devices.

- Cloud: Used to store and process massive amounts of IoT data, which are accessible to manufacturers for making data-driven decisions.

- Analytics: The process of converting raw data from IoT devices into actionable insights using algorithms and machine learning. It provides real-time analysis for anomaly detection and helps manufacturers perform predictive maintenance.

- Connectivity: Essential for ensuring effective data exchange and device connectivity.

- System Security: Protects IoT systems from vulnerabilities and attacks.

8 Advantages of IoT in Manufacturing Industry

Let’s look at some benefits of IoT in manufacturing:

Reduces Cost

Manufacturers face significant expenses related to energy, materials, and downtime. IIoT technology helps cut these costs and unlock new revenue streams. It enhances asset, inventory management and minimizes machine downtime. IIoT also helps manufacturers streamline operations and improve energy efficiency. Additionally, IoT-driven predictive maintenance helps prevent unexpected breakdowns and costly emergency repairs by identifying potential issues before they escalate.

Facilitates Predictive Maintenance

IoT devices provide real-time data that can be used to forecast potential defects in tools and machinery. This proactive approach minimizes downtime and boosts overall productivity. Additionally, it reduces costs associated with extended process times, and material waste, further enhancing operational efficiency.

Provides Quicker Market Launch

IIoT accelerates the time from product conception to market launch by improving the efficiency of manufacturing and supply chain operations. This facilitates direct communication between employees and networked systems. Manufacturers can speed up their decision-making process and responsiveness to market changes. These improvements enable a faster transition from product development to putting the products on the market in a shorter time.

Enables Mass Customization

One of the key IIoT benefits is its role in enabling mass customization. It helps manufacturers create a wide range of products and tools, leading to a diverse inventory. IIoT supports mass customization by providing real-time data for accurate scheduling and forecasting, effectively managing the complexity of varied inventory and production requirements.

Helps in Advanced Decision-Making

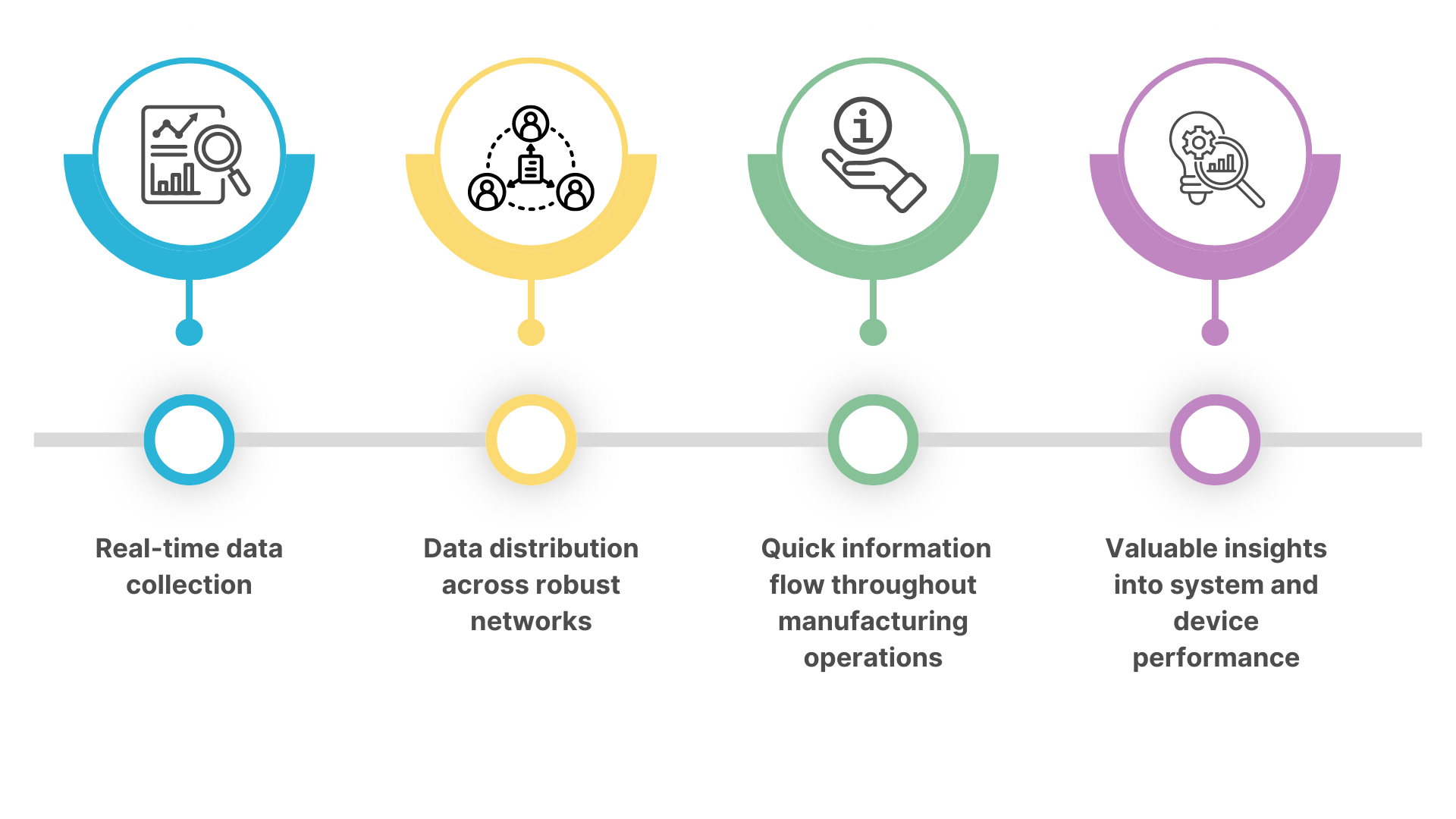

IoT in manufacturing enables manufacturers to take more informed data driven decisions by providing them with:

Enhances Efficient Facility Management and Quality Assurance

Previously quality assurance was a manual and error-prone task. However, with the integration of IIoT technology, manufacturers can now achieve precise monitoring of quality factors including humidity, temperature, and pressure.

By continuously assessing these factors, manufacturers can detect potential issues before those can create major impact on operations and provide early warnings. IoT sensors enable the collection of accurate data, which helps identify products that meet quality standards and those that require closer inspection. This allows manufacturers to provide timely interventions and prevent disruptions during manufacturing process. Especially beneficial for manufacturers adhering to rigorous quality standards such as ISO and GMP.

Ensures Safety Enhancements

Another advantage of implementing IoT in manufacturing is how it contributes to a safer working environment by –

- Monitoring workers’ health with wearable IoT devices

- Implementing indoor proximity systems for social distancing compliance

- Detecting and addressing hazard prone activities that could lead to injuries

- Identifying and mitigating safety hazards in potentially dangerous environments.

Optimizes Safety Management

Manufacturers are rapidly adopting wearable IoT devices as part of their safety management systems. These devices monitor factors such as employee posture, noise levels, and gas leaks on the shop floor, enabling real-time detection and fixing unsafe conditions. Utilizing these IIoT benefits help manufacturers oversee the overall safety by allowing timely interventions and improving working conditions in factories.

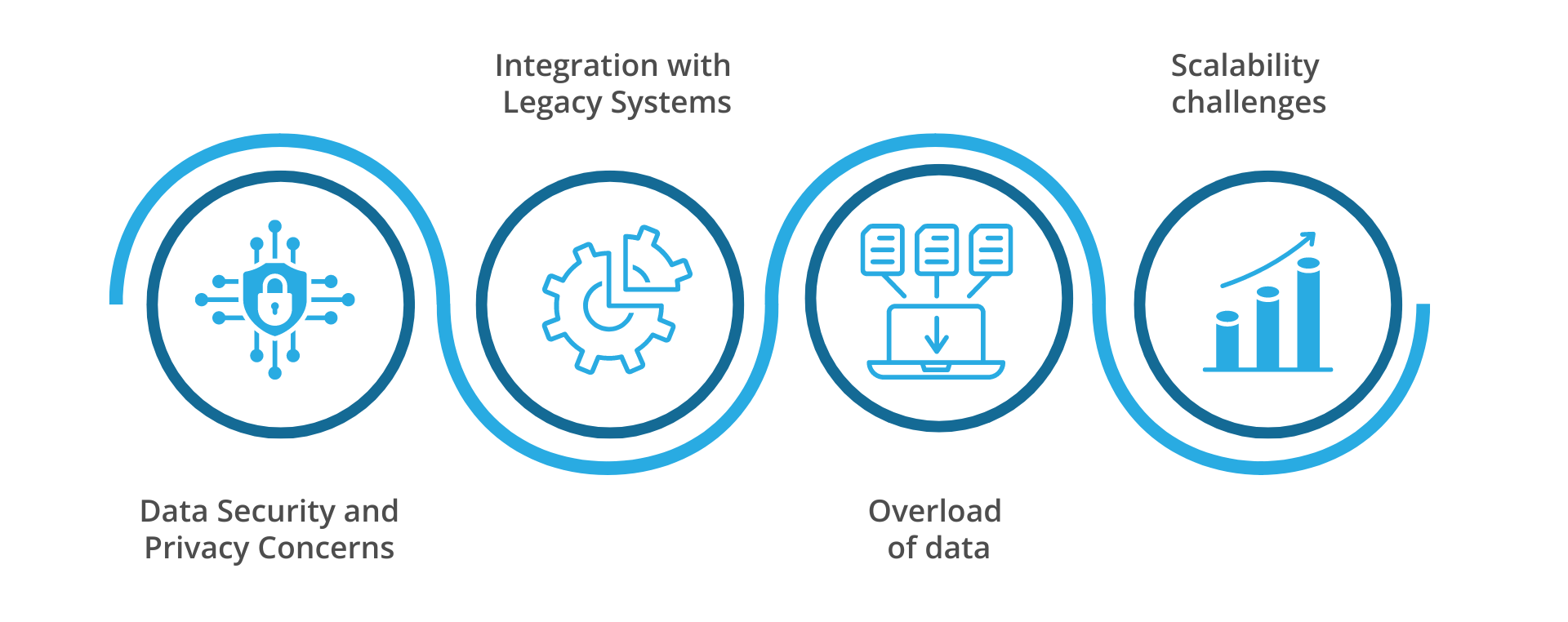

Challenges Faced by Manufacturing Industry in IoT Adoption

Implementation of IoT in manufacturing industry is becoming popular, but there are still some challenges that manufacturers face. These challenges are:

How Snowflake Helps Manufacturers Drive Profits?

Snowflake, with its advanced AI Data Cloud platform helps manufacturers to:

- Easily identify quality control issues

- Enhance data analytics

- Implement Predictive Maintenance in manufacturing process

- Eliminate data silos

Why Choose Kasmo?

As a true blue partner of Snowflake, Kasmo provides manufacturers with best solutions to tackle challenges in the manufacturing companies. Our experts leverage Snowflake to help clients implement IoT in manufacturing industry seamlessly. Manufacturing companies can transform their data to generate value by using our Snowflake Accelerators – Predictive Maintenance and Supply Chain AI Advisor Tools. Need more information on how these tools help? Connect with our experts now!