Introduction

Generative AI (Gen AI) is reshaping industries across the globe, with manufacturing and supply chain sectors at the forefront of this revolution. According to a McKinsey survey in 2023, it was observed that 79% of global executives are familiar with AI and 22% of CXOs are already using it. Integrating Gen AI in manufacturing enhances operational efficiency, improves supply chain management, streamlines inventory management and helps manufacturers stay prepared for any unforeseen challenges.

The use of Generative AI for manufacturing and supply chain operations unlocks new possibilities for process optimization, task automation, and opens new streams for generating revenue. By leveraging Gen AI, manufacturers can consolidate cross-functional insights, predict supply chain disruptions, and help design more efficient production lines.

The Role of Generative AI in Manufacturing Operations

Let’s get a comprehensive overview of how manufacturers can get the benefits by integrating Gen AI:

Improved Planning and Forecasting

Manufacturing enterprises heavily depend on planning activities which enable smooth production operations with minimal disruptions. The integration of Gen AI allows manufacturers to work faster on both market demands and streamline supply chain management. Manufacturers who implement advanced AI/ML models can unify data from sales, marketing and procurement departments, to develop better and more accurate forecasting models. With Gen AI, manufacturers can integrate both first-party and third-party data from consumers and historical data, enabling them to stay on top of manufacturing trends.

Gen AI actively helps manufacturers to elevate their operations and prevent frequent breakdowns in the supply chain. When inventory shortages or delays occur, Gen AI can capture this data and suggest alternative suppliers and production tactics which will help manufacturers continue operations smoothly in the future. These improvements help manufacturers become more agile and responsive to changing market conditions, reducing stockouts.

Enhanced Production

The success of manufacturing companies depends on how efficiently and quickly they are transforming raw materials into finished goods. Gen AI can significantly enhance this process by automating routine tasks, improving decision-making, and boosting productivity.

- Predictive Maintenance: Gen AI can predict when an equipment is likely to fail, enabling manufacturers to take preventive action before a breakdown occurs. By analyzing historical data and analyzing sensors mounted on machineries, Gen AI can forecast failure events with remarkable accuracy. This reduces downtime, extends equipment life, and helps manufacturers avoid costly repairs.

- Root Cause Analysis: Gen AI can also help identify the root causes of production inefficiencies and defects. Whether it’s an issue with the machinery, materials, or human error, AI-powered models can quickly analyze and pinpoint the cause of defects or delays, allowing manufacturers to resolve issues before they impact production schedules.

- Easy-to-Understand Instructions: In many cases, operators or customer service teams in manufacturing companies need clear, detailed instructions to carry out complex tasks. Gen AI can generate these instructions easily, adapting to the specific needs of the operation and providing easy-to-follow steps for workers. This ensures a more consistent and accurate production process.

- Augmented Reality (AR) and AI-Driven Assistance: By integrating AI with AR, your employees can get real-time, AI-supported troubleshooting solutions. This assists workers in troubleshooting issues without waiting for an expert, leading to faster issue resolution and less downtime.

Streamlined Delivery and Logistics

Manufacturers know that getting products to customers on time and without defects is a critical part of achieving success. Gen AI plays a key role in optimizing the delivery process, ensuring there are no roadblocks in logistics and customer expectations are met.

- Automating Document Generation: Gen AI can automate the generation of critical documents like invoices, shipping labels, and packing lists. This reduces the administrative burden on your employees, speeding up the process of preparing products for shipment.

- Order Tracking and Customer Communication: Gen AI-powered chatbots can handle routine customer inquiries regarding order status, shipment tracking, and delivery schedules. This frees up customer service representatives to focus on more complex issues while enhancing the customer experience.

- Digital Twin Technology: With Gen AI, manufacturers can create Digital Twins or digital replicas of physical warehouses or supply chains and simulate different production scenarios which will help them optimize warehouse layouts and product flow. This leads to more efficient warehouse management and faster order fulfillment.

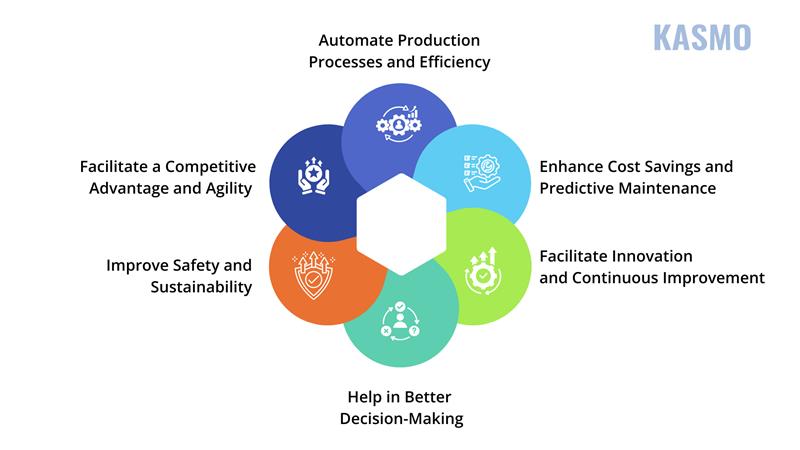

The Benefits of Integrating Gen AI in Manufacturing

The potential benefits of Gen AI in manufacturing are vast. As we step further into 2025, it is critical that you are ready for the new future of the manufacturing industry. From improving operational efficiency to reducing costs and fostering innovation, the impact of Gen AI is paving the way for smarter manufacturing:

Automate Production Processes and Efficiency

Gen AI in manufacturing accelerates production processes by automating repetitive tasks and optimizing workflows. From design to quality control, AI can take over time-consuming activities, allowing manufacturers to focus on more strategic and value-added tasks. AI-driven automation reduces human error, streamlines operations, and enhances efficiency.

Enhance Cost Savings and Predictive Maintenance

Gen AI helps identify bottlenecks and inefficiencies in manufacturing processes, leading to significant cost savings. By predicting equipment failures before they happen, manufacturers can reduce the need for expensive repairs and minimize downtime. Additionally, integrating AI in predictive maintenance also optimizes energy consumption, improves inventory management, and reduces waste, leading to more cost-effective manufacturing operations.

Facilitate Innovation and Continuous Improvement

Gen AI supports innovation in manufacturing by analyzing vast amounts of data to uncover insights and propose new ideas. Whether it’s suggesting new product designs or identifying ways to improve existing manufacturing processes, Gen AI can drive continuous improvement and help companies stay competitive. By facilitating faster prototyping, Gen AI enables manufacturers to quickly adapt to changing market conditions and consumer demands.

Help in Better Decision-Making

Gen AI in manufacturing empowers decision-makers or business leaders with real-time data and actionable insights. Through advanced data analysis, simulation models, and predictive capabilities, Gen AI supports informed decision-making across all levels of the manufacturing process. Digital twins, for example, allow manufacturers to test production scenarios and assess potential risks before implementation, ensuring more effective and data-driven decisions.

Improve Safety and Sustainability

AI-powered robots also contribute to a safer working environment by enabling the human workforce to collaborate with robots. These AI-driven robots can handle strenuous or hazardous tasks, reducing risks to human employees. Additionally, manufacturers can optimize resource allocation and minimize waste, reducing carbon footprint and maintaining sustainability in their regular operations.

Facilitate a Competitive Advantage and Agility

Manufacturers that adopt Gen AI can gain a significant competitive advantage by speeding up product development, improving quality control, and enhancing supply chain efficiency. The ability to quickly iterate on designs and production processes allows businesses to stay ahead of their competitors.

The Role of Snowflake AI Data Cloud in Manufacturing

To fully unlock the potential of Gen AI in manufacturing, you need a robust cloud platform. Snowflake for manufacturing provides an integrated platform that simplifies data operations and allows for real-time collaboration across the supply chain. By breaking down data silos and providing access to both IT and OT data, Snowflake enables manufacturers to power smart manufacturing initiatives, optimize production, and improve supply chain performance.

Partnering with Kasmo will help manufacturers to store and analyze amounts of data generated from devices on the shop floor. Our Snowflake powered solutions and accelerators are designed specifically for manufacturers who are looking to transform their operations and create better supply chain management. With Kasmo’s Snowflake accelerators you can get a holistic view of manufacturing operations, accelerate decision-making, improve productivity, and reduce your delivery time to customers by days!

Conclusion: The Future of Manufacturing is Already Here, Are You Ready?

The integration of Gen AI in manufacturing and supply chains has created a fundamental shift toward more efficient, intelligent, and adaptable manufacturing and supply chain management. From enhancing decision-making and improving operational efficiency to fostering innovation and sustainability, Gen AI has the power to reshape the future of manufacturing industry.

As new Gen AI-powered tools evolve, manufacturers need to be ready for this technology boom. Industry leaders who have already started to take measures and prepare their business models to adopt Gen AI are likely to stay relevant in this increasingly competitive and dynamic market. By embracing Snowflake AI Data Cloud platform and Kasmo’s accelerators, manufacturers can unlock new levels of productivity, reduce costs, and create strategies that can help them keep the supply chains and operations prepared for any sudden geopolitical or economic changes.

In this new age of AI-driven manufacturing where the possibilities are endless, and the benefits are just beginning to unfold, are you ready to integrate Gen AI in your business?