Understanding What is Supply Chain Management and Its Importance in the Manufacturing Industry

Supply chain management (SCM) is a series of steps that involve turning raw materials into finished products and delivering them to consumers. SCM plays a fundamental role in the manufacturing industry. It ensures that operations run smoothly, efficiently and as cost-effectively as possible.

Each step in the SCM depends on the previous step. Individually integrating each step is an optimal way for manufacturers to achieve the best performance. Effective SCM enables manufacturers to react quickly to changing market demands, increasing flexibility and responsiveness of the company.

The manufacturing industry has faced many disruptions during the pandemic. This has increased the significance of a robust supply chain. Manufacturers now want resilient supply chains that can withstand unexpected challenges. This realization has driven manufacturing companies to modernize their SCM practices, by leveraging IT and OT data to improve decision-making and operational efficiency.

According to a survey conducted by Statista in 2021, it is observed that almost 40% of supply chain industry professionals have started integrating cloud in their operations. However, there are many manufacturing companies that are yet to adopt cloud analytics to optimize their supply chain management.

To combat increasing fluctuating demand and shocks throughout the supply chain, manufacturers need to rely on accurate and data-driven insights to optimize their operations.

Importance of Supply Chain Management

Having an updated and advanced supply chain management can help manufacturing companies stay abreast of the competitive market. A proper supply chain helps manufacturers minimize waste and prevent them from making excess inventory. This also facilitates manufacturers to lower costs and increase efficiency. By having a smooth supply chain, manufacturers can guarantee an optimized customer experience and personalized logistics.

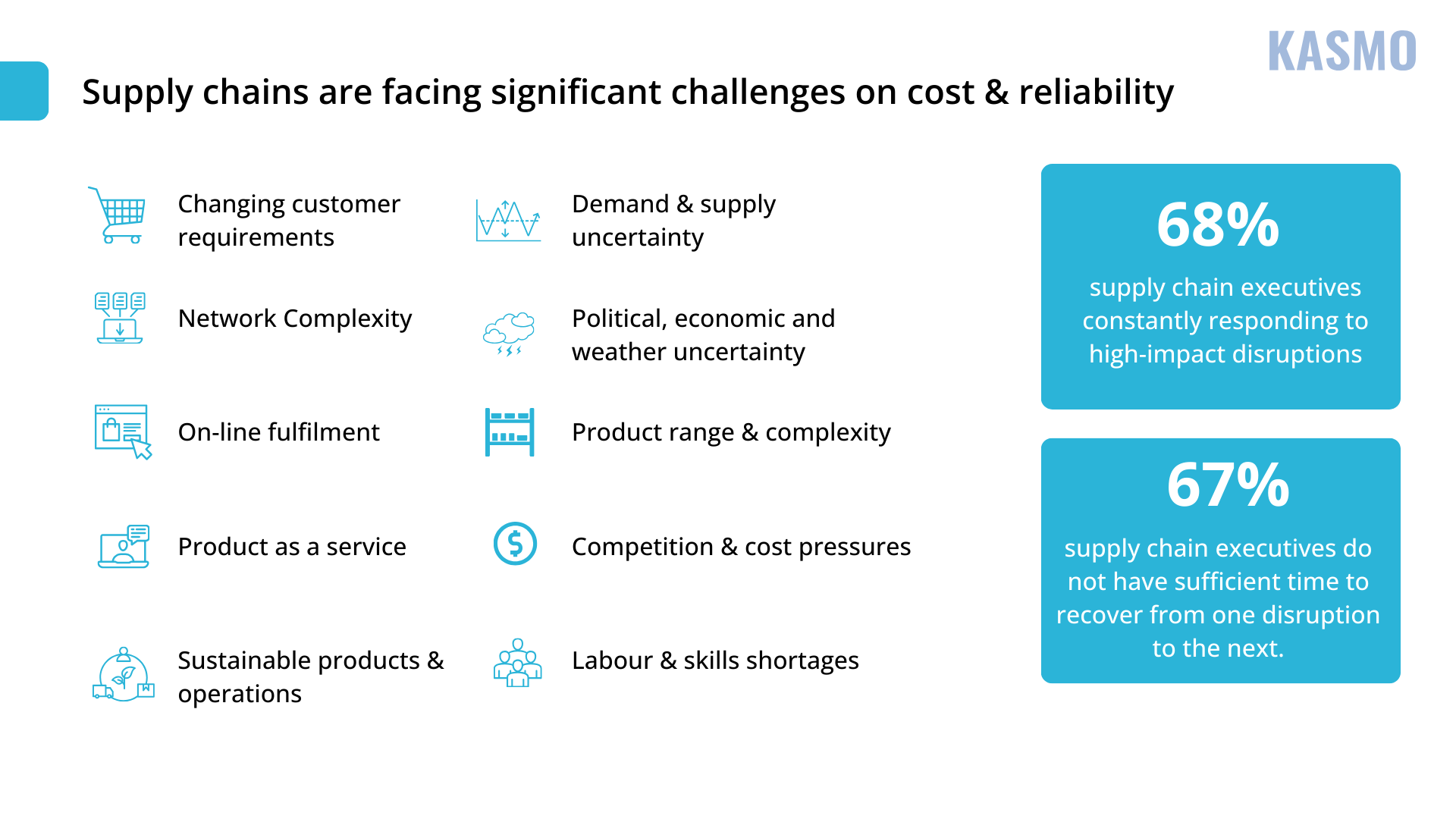

What Challenges Create a Roadblock for Manufacturers While Optimizing the Supply Chain?

Here are some challenges that are creating some roadblocks for manufacturers to adopt cloud analytics and optimize supply chain management:

- Since IT and OT are different entities in the manufacturing industry, if not integrated can create clashes while selecting a cloud provider. Sometimes a team handling IT data may prefer to stick to on-premise architecture for their data and the team handling OT data may want to move to cloud technologies or vice versa.

- Major manufacturing companies often lack a data warehouse that can store huge amounts of incoming data of different formats.

- Lack of computational power for different types of data creates a setback for manufacturers to understand supply chain analytics.

- The labor market for manufacturing is on a decline since the pandemic

- Historical architecture preventing manufacturers to collaborate easily

- Incomplete or no knowledge of how to use data for optimizing manufacturing operations.

- Less investment in technologies that can provide accurate supply chain analytics.

How Manufacturers Can Transform Supply Chain Management Using Data

As per a survey conducted by Gartner in 2023, almost 50% of companies have started using AI, advanced analytics and IoT to enhance the supply chain. Suppliers, distributors and manufacturers are now adopting more effective strategies to get the most out of the data gathered from the operations. Here are some more ways you can transform your supply chain management using data:

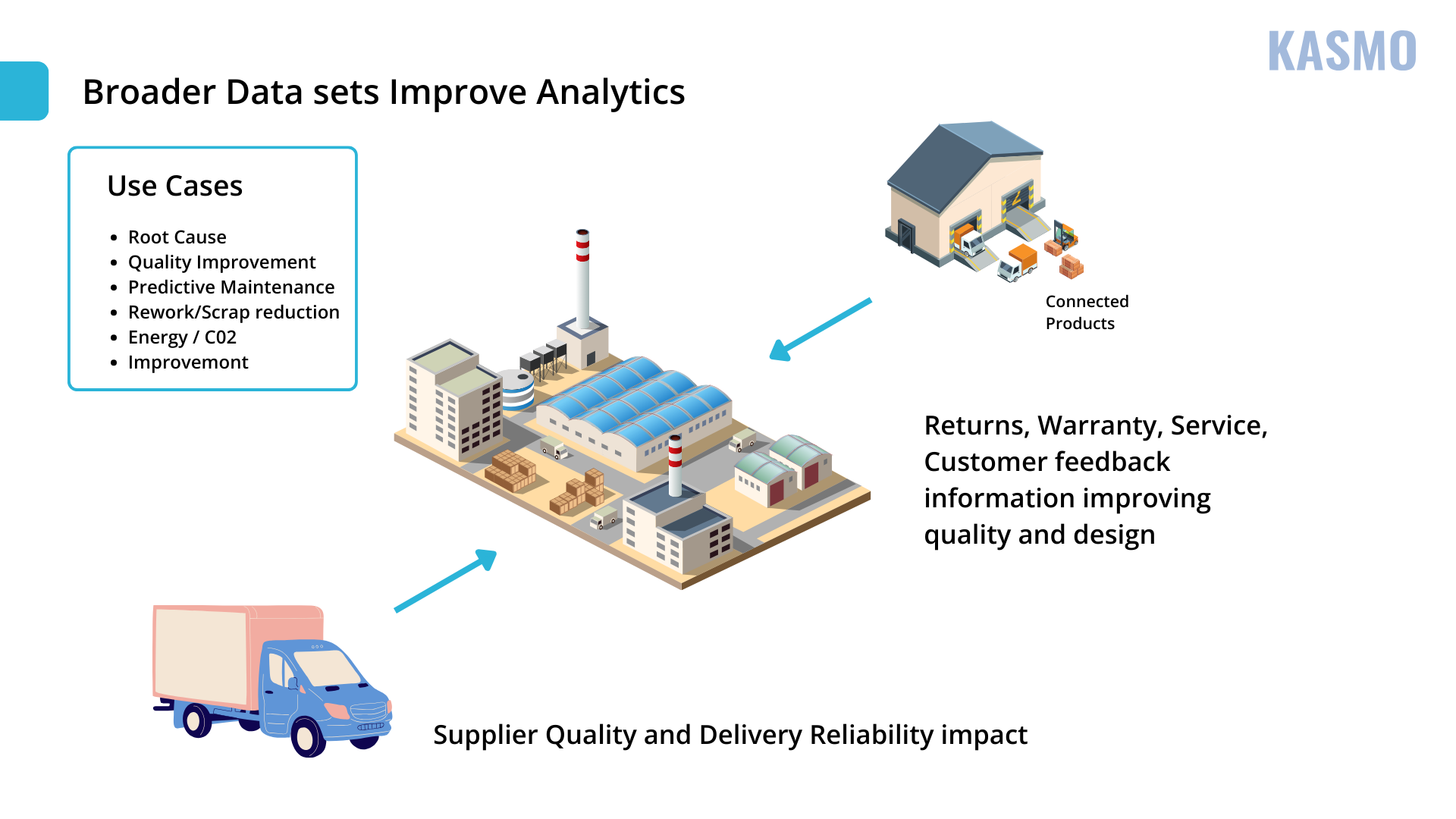

Integrate Data from Multiple Sources

A supply chain has multiple touchpoints from where manufacturers can gather data and utilize them to draw supply chain analytics. These sources are – Enterprise Resource Planning (ERP) systems, Warehouse Management Systems (WMS), Point of Sale (POS) systems, etc. Manufacturers can also gather data from external sources that can be integrated with the data from supply chains in a single repository to draw detailed analysis.

Enhance Collaboration

It is crucial to note that manufacturers need to gain a detailed visibility to take correct decisions for effective supply chain management. Integrating a robust cloud system increases visibility. This cloud system can facilitate manufacturers obtaining advance warnings on delays in shipments of raw materials required by production line, which can help them to stock in advance. By utilizing data, manufacturers can concentrate on inventory investment, move inventory within one manufacturing facility to another, or develop new methods that can accelerate the production of goods for shipment.

Implement AI and Machine Learning Models

As per a survey by Gartner, it is observed that 52% of manufacturing companies are more likely to use AI and automation by 2025. Implementing AI and Machine Learning Models, manufacturers can draw massive amounts of data to and analyze them to flag potential issues. AI and ML models can predict severe weather events, political unrest, port congestion and so forth, that facilitates manufacturers to take data-driven decisions.

Adopting Scalable Data Infrastructure

Manufacturers need to adopt data infrastructure that scales with increasing amounts of data. Manufacturers need a cloud infrastructure that can consume, process, store, and analyze huge quantities of data from different sources and in various formats.

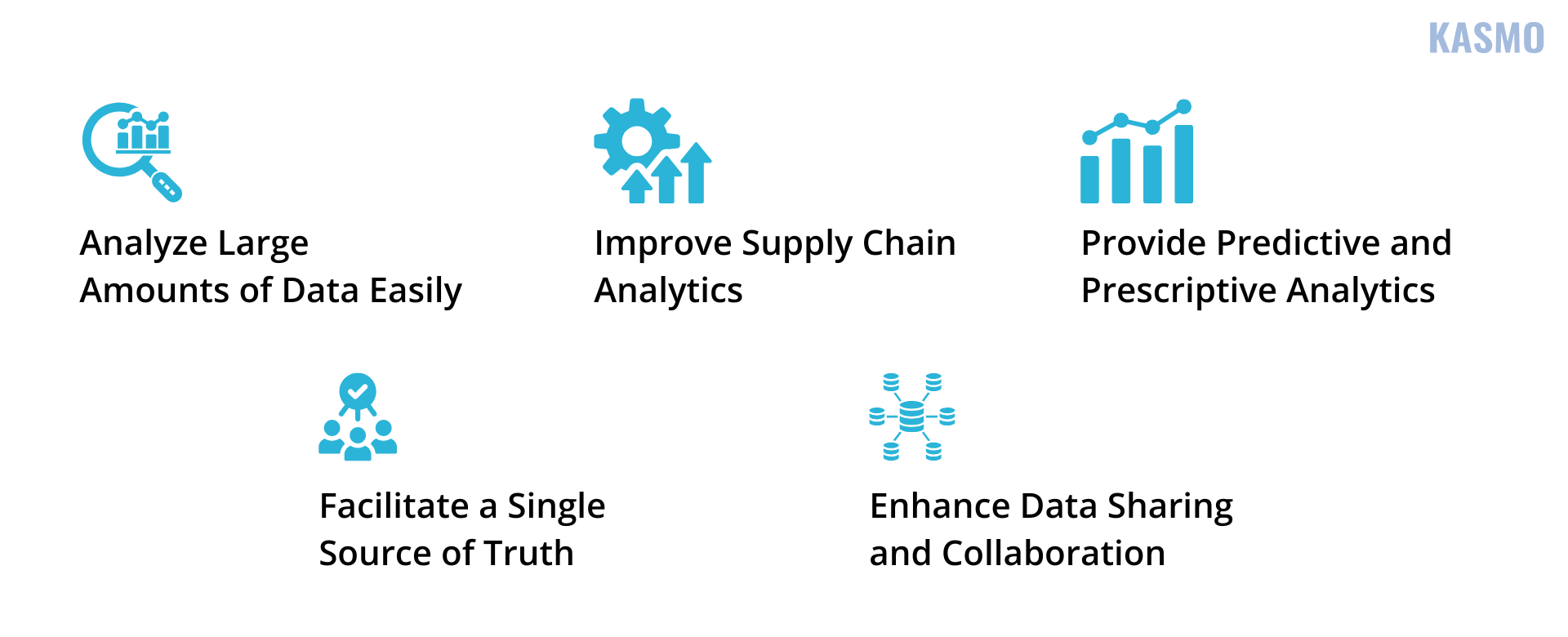

How Manufacturers can Derive Value By Implementing a Cloud Solution?

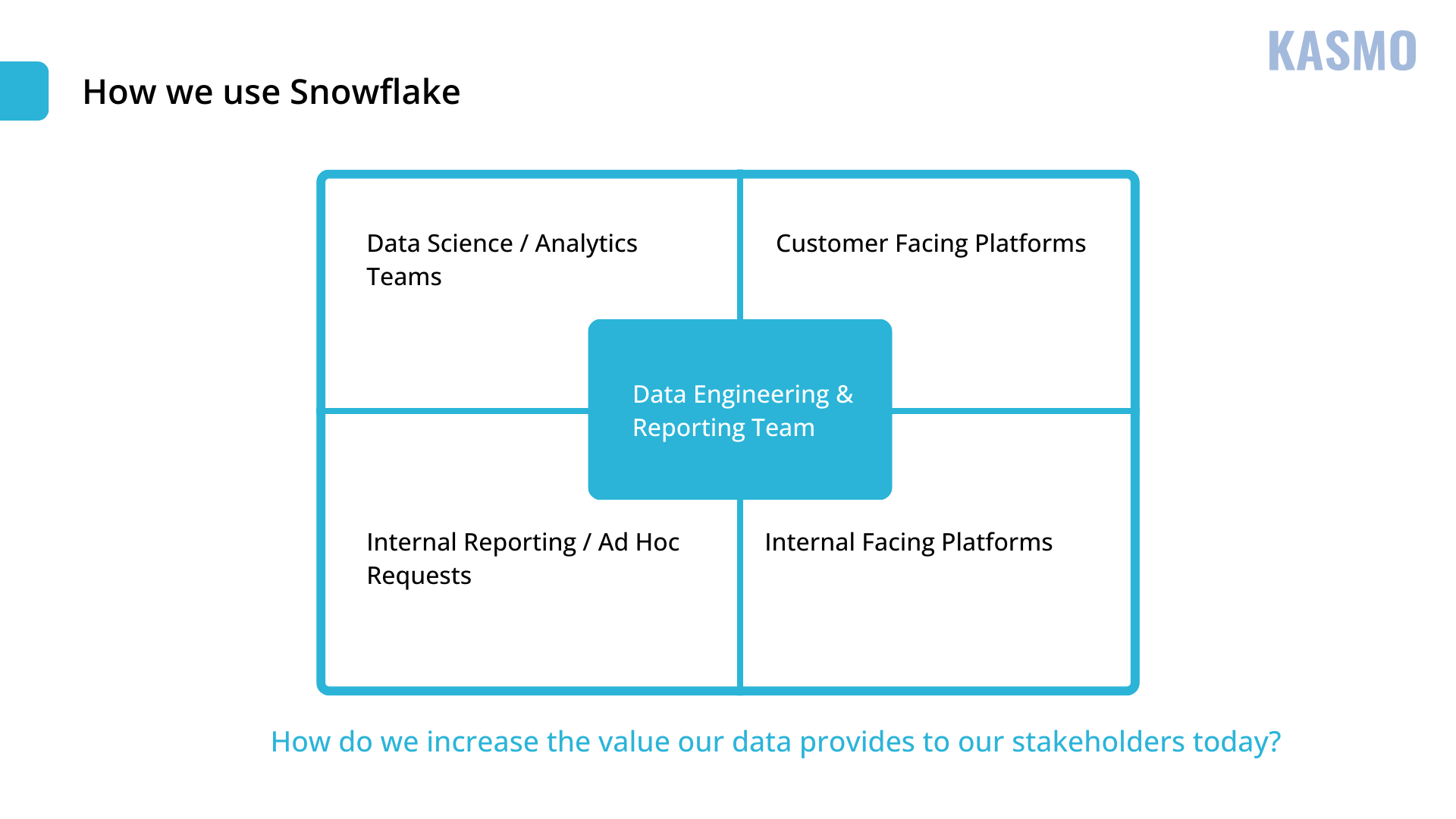

Why Choose Snowflake to Enhance Supply Chain Management?

Leveraging Snowflake AI Data Cloud can help manufacturers plan the inventory with forecasting models. They can also manage supply chain risk and project the availability of raw materials with Snowflake. Here are some more reasons why manufacturers should choose Snowflake:

Enhanced Visibility Across Supply Chain

Snowflake provides near real-time visibility into the supply chain, allowing organizations to access data from all sources. This approach allows manufacturers to take better decisions. The Snowflake AI Data Cloud platform also provides demand forecasting by integrating relevant third-party data from the Snowflake Marketplace. This allows manufacturers to respond quickly to market changes and consumer trends.

Advanced Data Analytics

The various resources and tools of Snowflake facilitate manufacturers to integrate data from multiple sources and execute advanced analytics for broader data sets, relevant to the supply chain. This helps manufacturers find the root cause for problems in their supply chain, improve the quality of their products, revisit the production process to reduce the growing number of scraps from products, and reduce carbon footprint and implement a practice of sustainability in their organization.

Accurate Demand Forecasts

Snowflake provides accurate demand forecasting that helps manufacturers maintain optimal stock levels. Snowflake’s integration with multiple data sources helps manufacturers align inventory with actual demand. By leveraging advanced analytics and machine learning capabilities, manufacturing companies can reduce excess inventory and ensure they meet customer needs effectively.

Increased Collaboration and Data Sharing

Snowflake fosters data sharing and collaboration across different stakeholders in the supply chain. This helps manufacturers make informed decisions on product strategy and promotions. Data sharing streamlines operations and drives profitability through shared knowledge.

Scalable Data Architecture

As data volumes continue to grow, Snowflake offers near-infinite scalability. Organizations can store vast amounts of structured, semi-structured, and unstructured data without compromising on performance. The computational power of Snowflake ensures that data queries are executed efficiently, enabling businesses to capture and utilize all relevant data.

Robust Security and Governance

Snowflake’s advanced security features allow manufacturers to remain at par with data governance policies. With advanced user access controls and end-to-end encryption for data, manufacturers can ensure sensitive data remains protected while still being able to access data.

Benefits of Using Snowflake AI Data Cloud for Manufacturing

- Snowflake provides a unified platform for end-to-end Gen AI and ML, reducing the time taken for development and democratize ML for the entire organization.

- Data and AI infrastructure is integrated fully in Snowflake’s infrastructure, making it easy for manufacturers to uses AI through no-code Studio, SQL, Python and REST APIs interfaces.

- Now manufacturers can efficiently streamline the process of development-to-deployment with Snowflake’s innovative AI models and frameworks.

- Snowflake’s unified governance for data and models protects the manufacturer’s IP at scale, earning the trust of numerous organizations.

Snowflake provides more benefits to manufacturers which helps them to make their supply chain resilient, such as:

- Perform app development through Studio, Notebooks, Streamlit and Copilot

- Build Gen AI applications and swiftly analyze data for your supply chain through Cortex AI.

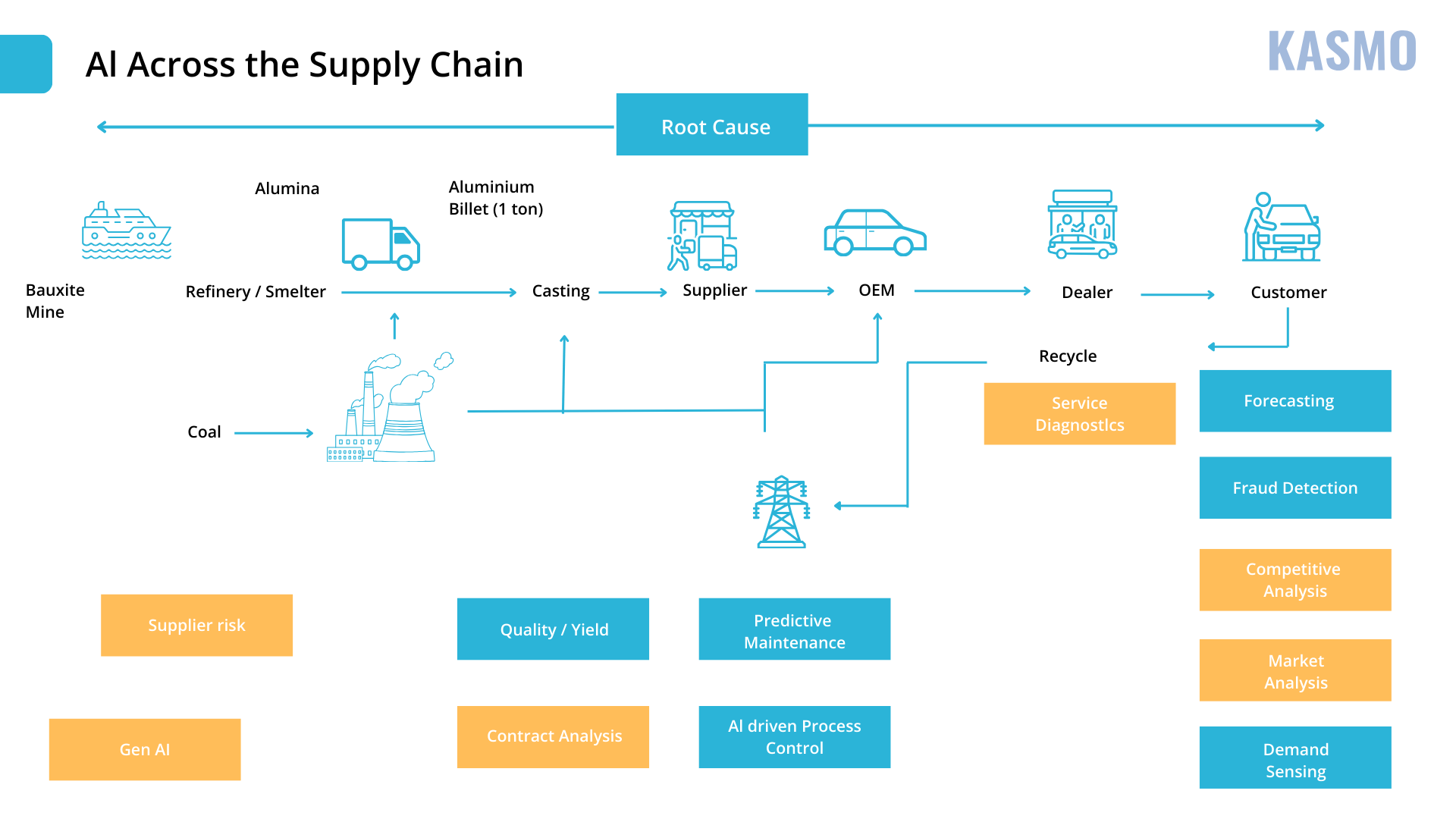

Let us observe how AI across Supply Chain can help manufacturers:

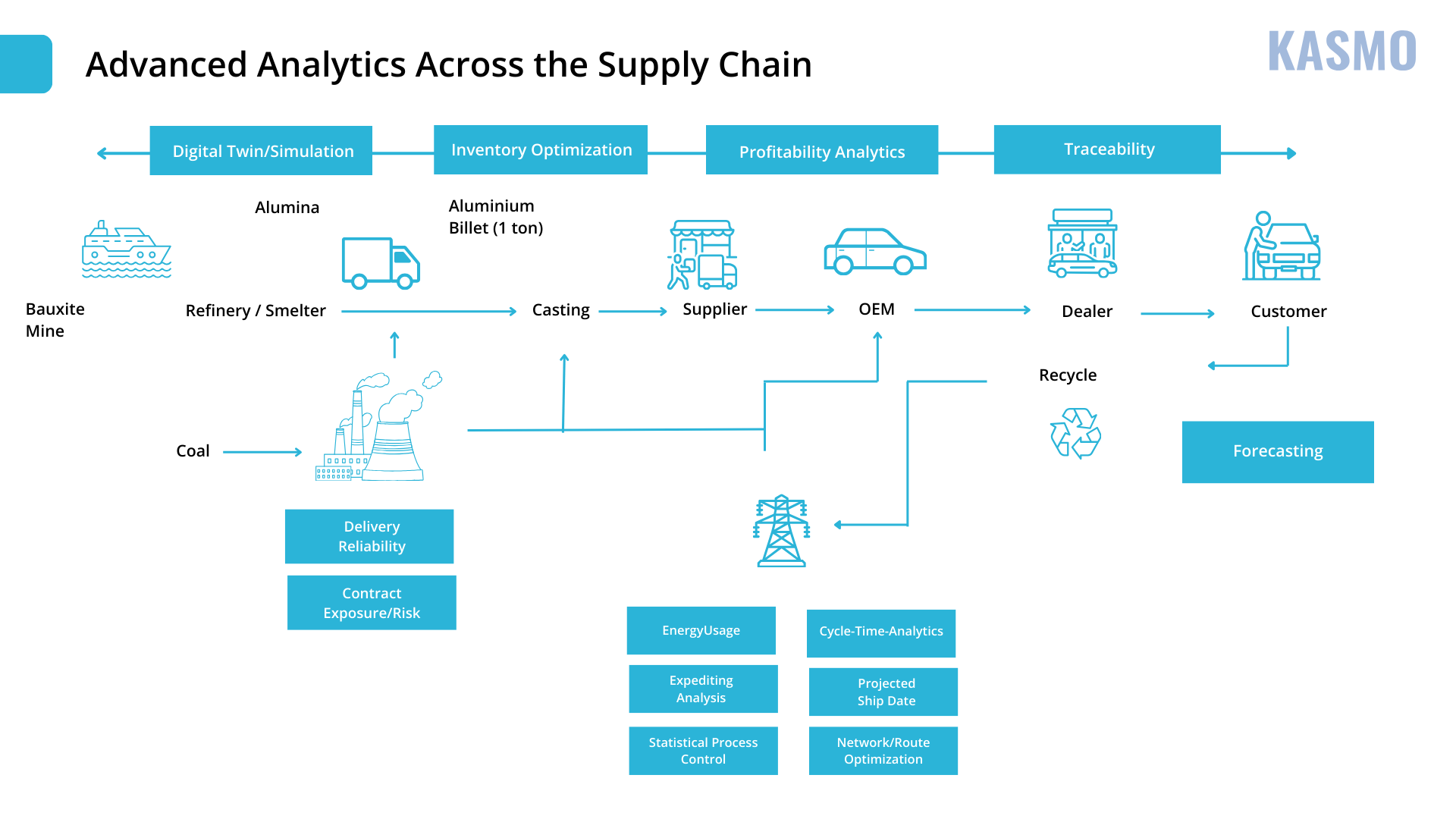

Implementing advanced analytics, manufacturers can build a resilient supply chain. Here’s how:

Conclusion

As the manufacturing industry continues to evolve, it is critical that supply chain management should be able to help manufacturers optimize supply chain processes, reduce waste and respond more quickly to customer needs. By integrating data from many sources, Snowflake allows manufacturers to enhance demand forecasting and data sharing with stakeholders, leading to efficiency and profitability. Using data analytics manufacturers can streamline supply chain and build a resilient supply chain management.