Introduction

Supply chain challenges pose significant hurdles for manufacturers aiming to enhance customer satisfaction and optimize profitability. From sourcing raw materials to ensuring timely delivery to consumers, manufacturers face issues like inventory management, demand forecasting, and logistics inefficiencies.

These complexities delay manufacturers from responding quickly to demands, elevating costs. To tackle these challenges deftly, manufacturers are now turning towards supply chain analytics, which offers a powerful solution. By leveraging data across each component of the supply chain, manufacturers can quickly identify inefficiencies, make informed decisions, and uncover new opportunities for cost reduction.

Supply chain analytics enables organizations to address immediate challenges, fostering long-term strategic improvements. With the right insights, manufacturing companies can enhance their operational efficiency, adapt to market demands, and elevate customer experiences.

Role of Supply Chain Analytics in Manufacturing

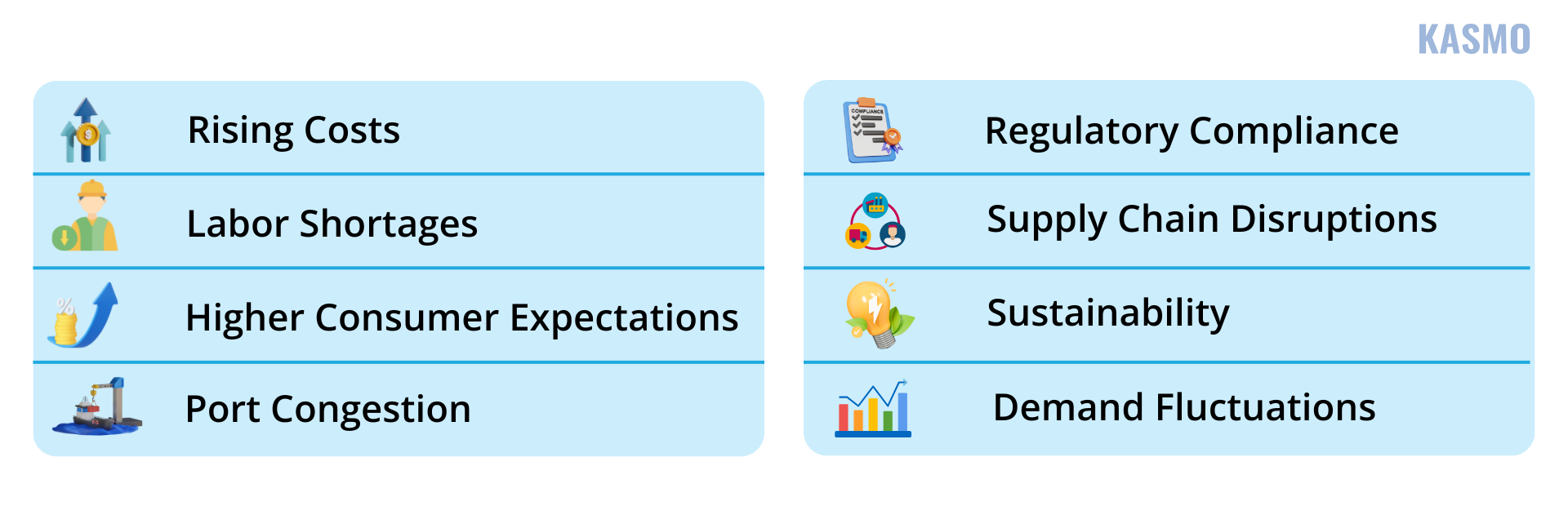

Manufacturers are constantly struggling with supply chain challenges:

To tackle these complex supply chain challenges, manufacturers need to understand – what is supply chain analytics?

Supply chain analytics involves analyzing data generated by a company’s systems and applications to uncover patterns and gain insights into its supply chain. This data provides visibility across major areas such as procurement, inventory management, order management, warehousing, fulfillment, and shipping.

Since supply chains are complex, there are numerous potential failure points that can disrupt operations and affect subsequent steps. By leveraging insights from their data, manufacturers can solve all kinds of supply chain problems, achieve high levels of customer satisfaction and control costs. This ensures a more resilient supply chain management.

How This Analytics Can Solves Supply Chain Challenges?

Supply chain analytics integrates data from various applications, infrastructure, third-party sources, and emerging technologies like the Internet of Things (IoT) to enhance decision-making across strategic, tactical, and operational processes in supply chain management. By improving real-time visibility into these processes, supply chain analytics helps synchronize planning and execution.

This creates a positive impact on customer experience and enhances profitability. It also increases visibility, fostering flexibility in the supply chain network and enabling decision-makers to better evaluate costs.

The development of supply chain analytics begins with data scientists who focus on specific business aspects, such as cash flow, inventory management, waste reduction, and service levels. They combine different data elements and create predictive models that optimize supply chain performance. Through rigorous testing and iteration, they refine these models until they achieve a high level of accuracy.

Type of Supply Chain Analytics Manufactures Need to Integrate

Here are some different types of supply chain analytics that manufacturers can leverage:

Descriptive Analytics

Descriptive analytics provides a comprehensive view of the supply chain. This type creates a single source of truth for both internal and external systems and data. It also allows visibility to manufacturers which helps them understand current operations and performance metrics clearly.

Predictive Analytics

Predictive analytics in supply chain enable manufacturers to forecast potential outcomes and business implications. For instance, by employing predictive analytics, manufacturers can identify and address possible supply chain challenges, such as disruptions and risks before they escalate, allowing for proactive management.

Prescriptive Analytics

Prescriptive analytics focuses on problem-solving and collaboration, which maximizes business value. It enables manufacturers to work closely with logistics partners. This enhances them to streamline processes and minimize disruptions, enhancing efficiency and response times.

Cognitive Analytics

Cognitive analytics empowers manufacturers to tackle complex supply chain challenges using natural language processing, which generates human-like responses. This type of supply chain analytics assists teams in exploring intricate problems, such as identifying ways to optimize specific steps in the supply chain.

Industries Which Can Use Supply Chain Analytics

Benefits of Utilizing Supply Chain Analytics in Manufacturing

Supply chain analytics is a powerful tool that enables manufacturers to tackle supply chain challenges and enhance profitability. By leveraging data from various sources, this analytics provides insights that address key challenges in supply chain management.

Enhanced Visibility

Supply chain analytics offers a comprehensive view of the entire supply chain, integrating data from multiple sources into a centralized platform. This visibility allows manufacturers to analyze all the data in a single place – making it easier to spot patterns and anomalies that can optimize performance.

Improved Understanding of Risks

Supply chain analytics helps manufacturers identify both known and potential future risks. By analyzing data trends, they can proactively plan for disruptions and mitigate their impact on delivery capabilities.

Optimized Risk Handling

When faced with numerous supply chain challenges, manufacturers can quickly identify the root cause of the problem through supply chain analytics. Real-time data analysis alerts manufacturing companies to take swift action and prevent minor issues from escalating into major operational challenges.

Improved Customer Experience

Effective planning and rapid response to supply chain challenges enhances customer satisfaction. By consistently meeting delivery deadlines, manufacturers can foster customer loyalty and reduce customer churn.

Accurate Demand Planning

By utilizing customer data to predict demand, supply chain analytics assists manufacturers in prioritizing products that are required for regional needs. This insight facilitates faster product development and inventory management, ensuring manufacturers keep up with customer expectations.

Increased Profitability

Supply chain analytics helps manufacturers monitor and reduce costs. By identifying opportunities for increased efficiency, they can significantly enhance profit margins.

Better Forecasting

Advanced supply chain analytics processes both structured and unstructured data, providing manufacturers capability to predict probable supply chain challenges. Timely alerts help manufacturers identify gaps, minimize risks and support sustainable practices.

Why Choose Snowflake to Tackle Supply Chain Challenges?

If you are wondering how to implement supply chain analytics to optimize your supply chain, leverage Snowflake. With the Snowflake Data Cloud, manufacturers can seamlessly integrate data from multiple sources and ensure quality and security through its robust governance policies.

Manufacturers can integrate call records, weather information, economic indicators, and sensor data with Snowflake’s advanced tools and resources. This facilitates manufacturers to gain insights and enhance operational efficiency.

Key Benefits of Leveraging Snowflake for Supply Chain Analytics

Here are some key benefits that you can get by leveraging Snowflake for Supply Chain Analytics:

- Faster Data Processing: With its high-performance architecture, Snowflake allows for rapid data analysis. Manufacturers can execute complex SQL queries efficiently, without considering the data volume.

- Unify data: Centralizing data eliminates integration and interoperability issues, enabling manufacturers to gain insights faster. This speed empowers manufacturers to make timely and informed decisions, crucial for maintaining competitive advantage.

Conclusion

Tackling modern day supply chain challenges efficiently and quickly can save manufacturers from facing severe losses. By leveraging supply chain analytics, manufacturers can analyze different types of data from various sources and gain valuable insights. These insights enhance visibility, improve risk management, and optimize operations.

The adoption of descriptive, predictive, prescriptive, and cognitive analytics allows for a more proactive approach to addressing supply chain challenges, leading to improved customer satisfaction and increased profitability. By leveraging Snowflake, manufacturers can enhance their supply chain analytics, driving better decision-making and improved outcomes across their operations. With Snowflake and Kasmo’s expertise they can build resilient supply chains that respond to current demands and adapt to future challenges, fostering long-term success.