Introduction

Manufacturers often face challenges related to data which inhibit their growth in innovation and excel in customer experience. To drive analytics from data and utilize it to propel towards innovating new products, manufacturers have started to take help from Information Technology (IT) and Operational Technology (OT). OT governs the physical aspects of production, including machinery and devices, while IT manages the digital infrastructure. There’s a difference that exists between IT and OT due to their differing languages, processes, and priorities. If this difference is mitigated, companies can continue to grow sustainably in the future. With IT and OT convergence, manufacturers can focus on innovating new products and optimizing their processes.

Wondering how? Let’s begin!

What is IT and OT convergence?

IT/OT convergence is the integration of Information Technology (IT) systems with Operational Technology (OT) systems. This combination facilitates real-time data exchange and boosts the efficiency and effectiveness of both domains. By merging these systems, manufacturing companies can gain access to accurate, timely data that enhances decision-making and optimizes operational processes.

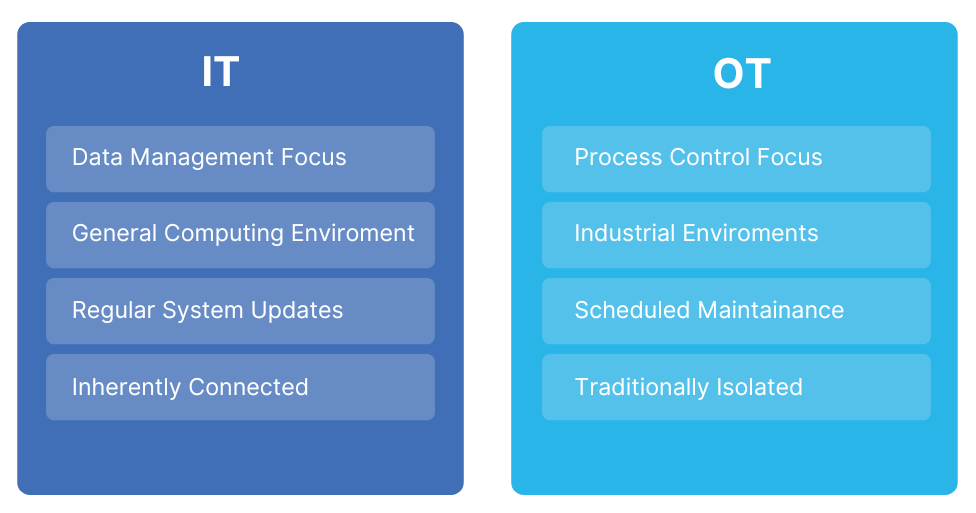

Difference between IT and OT

Why IT and OT Convergence Necessary in Manufacturing?

The IT OT convergence is driven by digital transformation and advancements in technologies such as the Internet of Things (IoT). The integration of IT and OT facilitates a smooth data exchange between the digital and physical systems, bridging the gap between data management systems and industrial operations. This convergence impacts the operational process by improving efficiency and innovation in business processes.

How does Snowflake Facilitate IT OT Convergence in Manufacturing?

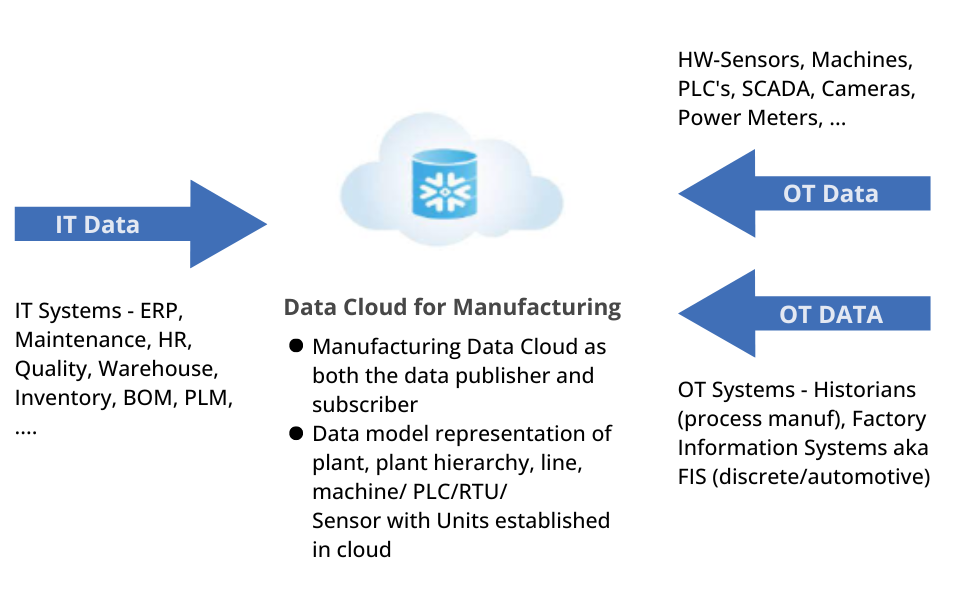

Snowflake is dedicated to unifying IT and OT data to empower businesses with insightful data, which results in a successful IT/OT convergence. This process involves precise asset identification, understanding plant hierarchy, and secure data sharing with clients and partners. Snowflake’s robust platform facilitates incorporation of IT data from ERP, CRM, and Supplier Relationship Management (SRM) systems.

Snowflake has formulated a standardized reference architecture to tackle any challenge manufacturers may face while IT/OT convergence. This architecture provides scalable, swift, adaptable, and secure communication between Snowflake and manufacturing companies. By adopting this integrated data architecture, Snowflake redirects the focus of users from merely constructing data ingestion solutions to utilizing data which drives crucial business results. This involves enhancing energy and asset performance, facilitating predictive maintenance, and improving quality.

Discover how Kasmo’s innovative solutions help manufacturers: https://www.kasmodigital.com/snowflake/

Role of IT and OT Convergence in Manufacturing Industry

Here’s how IT OT convergence plays a vital role in transforming the manufacturing industry:

- Optimizes Efficiency: IT/OT convergence enables manufacturers to identify inefficiencies accurately, saving time and resources. For instance, monitoring air compressor trends can help identify energy inefficiencies early, leading to predictive maintenance and significant savings.

- Improves Supply Chain: The IT OT convergence in the manufacturing industry provides efficient supply chain management and enhances coordination and planning, which helps manufacturers during unexpected disruptions.

- Introduces Sustainability: Real-time data allows manufacturing companies to monitor and optimize energy consumption, reduce waste, and enhance resource usage, aligning with evolving sustainability standards.

- Facilitates Closed-Loop Quality: IT OT convergence fosters a closed-loop manufacturing approach. This provides data insights to refine product designs and optimize production. This process ensures continuous quality assurance in case of any design improvements.

- Provides Rich Data Collaboration: Real-time data from the factory floor is integrated into IT systems, enhancing decision-making. This data supports the implementation of digital twins (virtual representations of physical entities), which enhances production efficiency.

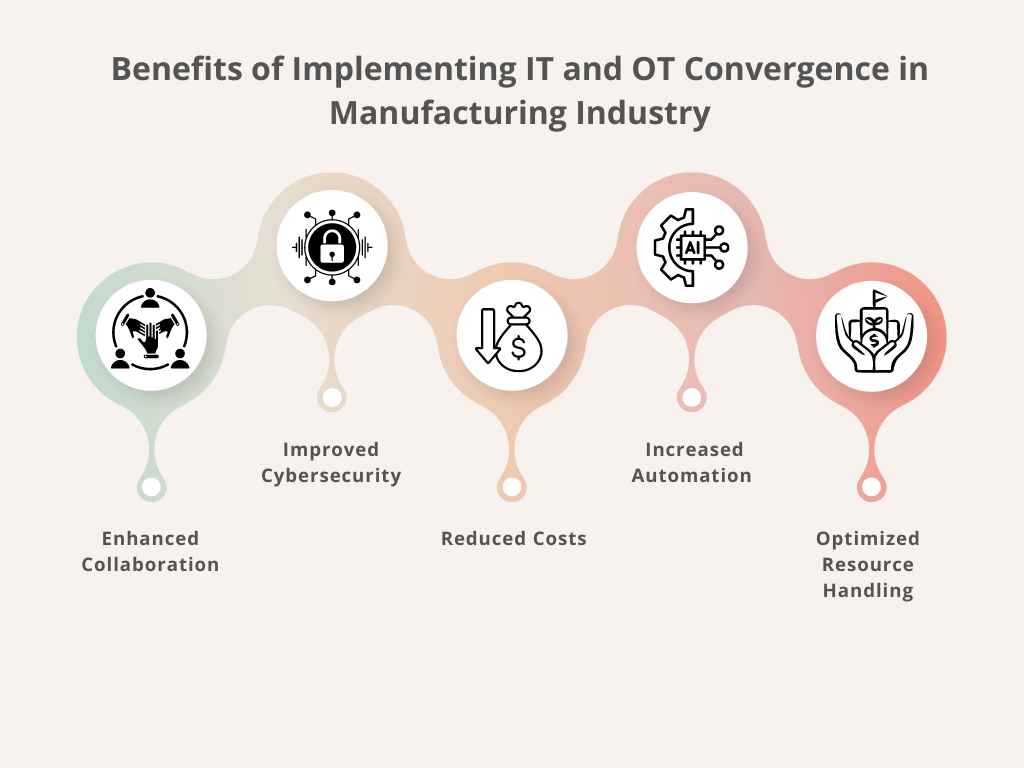

Key Benefits of Implementing IT and OT Convergence in the Manufacturing Industry

These are some key benefits of implementing IT and OT convergence in manufacturing industry:

How Manufacturers can Benefit from Integrating IoT and IT/OT Convergence?

First let’s understand the basic difference between IoT and IT/OT convergence. IT/OT convergence is about integrating two different types of technology systems within a business, while Internet of Things (IoT) is about connecting everyday objects to the internet to collect and use data. So, how does the integration of IT/OT and IoT help manufacturers?

By integrating IoT and IT/OT, manufacturers can gather data from advanced smart sensors directly from the source, such as a manufacturing plant, and transmit it to an IoT hub or gateway. This hub or gateway then relays the information to an analytics application or an Enterprise Resource Planning (ERP) software platform, allowing it to be incorporated into a company’s integrated business operations system.

When connected to a network, an OT device operates as an IoT device. For instance, on a factory floor, a sensor could gather operational data about materials or machinery and wirelessly transmit it to a back-end system application. This data is then interpreted and can initiate an action, such as scheduling maintenance for factory equipment.

How Snowflake can Help Manufacturers in this Integration?

For the creation of data-driven insights, manufacturing companies require a robust cloud platform equipped with data pipelines capable of integrating both IT and OT data on a large scale. Ideally this platform must also promote the convergence of IT and OT by establishing a detailed asset model and plant hierarchy in the cloud, combined with AI/ML capabilities. Let’s have a look:

Snowflake recognized the requirement for manufacturers to store and integrate all their data in a single unified platform, and created AI Data Cloud for Manufacturing. The platform is equipped with data pipelines that can handle both IT and OT data, to enable their integration.

How can Kasmo help Manufacturers?

Leveraging the Snowflake Data Cloud platform for manufacturers, Kasmo has created an innovative solution for manufacturing companies – Predictive Maintenance Solution. It is an advanced comprehensive solution, created by leveraging advanced machine learning models to solve common challenges like inventory management, over-allocation of resources and keeping up with rapidly changing consumer trends. Interested in learning more about how this solution works? Connect with our experts!

Conclusion

The IT and OT convergence is transforming the manufacturing industry by merging digital and physical systems. It enhances operational efficiency and fosters innovation. By integrating IT systems with OT systems, manufacturers can get real-time data which helps in decision-making, optimize operations and improve business performance. With Snowflake AI Data Cloud, manufacturers can utilize its suite of resources to ensure seamless data management and analysis.

Additionally, IT/OT convergence helps manufacturers to handle challenges such as supply chain disruptions, sustainability goals and inefficiencies in process visibility. Kasmo’s advanced solutions like predictive maintenance improve operations, reduce waste and ensure a continuous quality enhancement. The integration of IoT with IT/OT further boosts these benefits by enabling real-time data collection and actionable insights. As manufacturing companies evolves, embracing IT and OT convergence is crucial to stay ahead in the market and have steady growth.